Revolutionizing Precision: Unveiling the Power of Fiber Laser Cutting Machines in 2D, 3D, and Tube Cutting

In the dynamic landscape of manufacturing, the advent of Fiber Laser Cutting Machines has emerged as a transformative force, redefining precision in 2D, 3D, and Tube Cutting processes. This comprehensive article explores the capabilities of these cutting-edge machines, shedding light on their applications, advantages, and the future they herald.

Understanding the Basics: Fiber Laser Technology

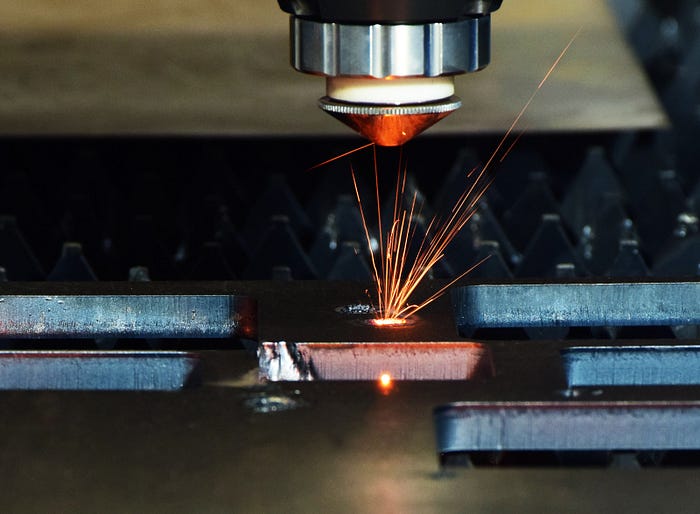

1. The Essence of Fiber Lasers

Fiber lasers operate on a unique principle, utilizing optical fibers doped with rare-earth elements to amplify light. This results in a highly concentrated and powerful laser beam, ideal for intricate cutting tasks. The technology’s inherent efficiency and precision make it a game-changer in various industries.

2. 2D Cutting Mastery

In the realm of 2D Fiber Laser Cutting Machines stand out for their unparalleled precision and speed. From intricate patterns to straight cuts, these machines excel in transforming raw materials into precise components. The flexibility they offer caters to diverse industries, from automotive to electronics.

3. Breaking into the Third Dimension

Venturing into the 3D Fiber Laser Cutting Machines bring a new dimension to manufacturing. Their ability to navigate complex geometries with precision opens doors to limitless design possibilities. Whether it’s creating artistic sculptures or crafting intricate components, the versatility of these machines knows no bounds.

Specialized Expertise: Tube Cutting Capabilities

4. Mastering Tube Cutting Challenges

The unique challenges posed by tube cutting find an effective solution in fiber laser tube cutting machines. With advanced focusing capabilities and rapid cutting speeds, these machines ensure clean and precise cuts on various tube profiles. The adaptability of Fiber Lasers makes them indispensable in industries where tube cutting is a critical component.

Advantages That Redefine Manufacturing Standards

5. Unrivaled Speed and Efficiency

Laser Cutting Machines are synonymous with speed and efficiency. The rapid cutting speeds, coupled with minimal downtime, translate to enhanced productivity. Manufacturers embracing this technology witness a significant boost in overall operational efficiency.

6. Precision Beyond Comparison

Precision is the hallmark of Fiber Laser Technology. The ability to make micro-cuts with utmost accuracy not only reduces material waste but also elevates the quality of finished products. In industries where precision is non-negotiable, Fiber Lasers are the ultimate choice.

The Future Landscape: Innovations on the Horizon

As technology continues to evolve, so do Fiber Laser Cutting Machines. The integration of artificial intelligence, automation, and enhanced connectivity promises a future where these machines operate seamlessly in smart manufacturing environments. This evolution not only enhances efficiency but also sets the stage for unparalleled advancements in the manufacturing sector.

Conclusion: Transforming Possibilities with Fiber Laser Cutting

In conclusion, Fiber Laser Cutting Machines have emerged as the driving force behind a manufacturing revolution. From mastering 2D and 3D cutting to tackling the intricacies of tube cutting, these machines redefine the possibilities in precision engineering. As industries increasingly adopt Fiber Laser Technology, they not only keep pace with current manufacturing demands but also position themselves at the forefront of innovation, ready to shape the future of manufacturing.

.png)

Comments

Post a Comment