Unveiling Excellence: A Comprehensive Guide to Launching Your Aluminium Fabrication Business

Embark on a transformative journey into the realm of aluminium fabrication with our comprehensive guide. We explore the strategic move of Embarking on an Aluminium Fabrication Business and highlight the myriad opportunities awaiting entrepreneurs within the dynamic Aluminium Industry.

Getting Started

Before delving into the intricacies of aluminium fabrication, understanding the foundational steps is paramount.

A. Legal Requirements and Regulations

Navigate the regulatory landscape diligently. Ensure compliance with local and industry-specific regulations, securing the necessary permits and certifications. This not only instills trust in your clients but also safeguards your business from potential legal challenges.

B. Crafting a Solid Business Plan

Crafting a robust business plan sets the stage for success. Outline your goals, target market, and unique selling propositions. A well-structured plan serves as a roadmap, guiding your business through the initial stages and positioning it for long-term success.

Setting Up Your Workspace

Establishing an efficient workspace is crucial for optimal operations in the aluminium fabrication sector.

A. Choosing the Right Location

Select a location that aligns with your business goals. Proximity to suppliers, accessibility for clients, and compliance with zoning regulations should factor into your decision-making process. A strategically chosen workspace sets the stage for operational efficiency.

B. Investing in Essential Equipment and Tools

Equip your fabrication facility with cutting-edge machinery. The efficiency of your operations heavily relies on the tools at your disposal. Invest in Aluminium Sheet Cutting Machines that align with the scope of your business, ensuring precision, speed, and versatility in your fabrication processes.

Types of Aluminium Sheet Cutting Machines

Understanding the nuances of cutting technologies is pivotal in the aluminium fabrication realm.

A. Shearing Machines: An Overview

Shearing machines, known for their simplicity, provide precise cuts for thinner aluminium sheets. Ideal for beginners, these machines offer reliability in the initial stages of aluminium fabrication.

B. Waterjet Cutting: Precision with Water and Abrasives

For intricate designs and precise cuts, waterjet cutting machines utilize a high-pressure stream of water mixed with abrasives. This technology ensures accuracy, making it suitable for a range of aluminium thicknesses.

C. Plasma Cutting: Efficient and Versatile

Plasma cutting machines, known for their efficiency, are versatile in handling medium-thickness aluminium sheets. Their adaptability makes them a valuable asset in a variety of fabrication scenarios.

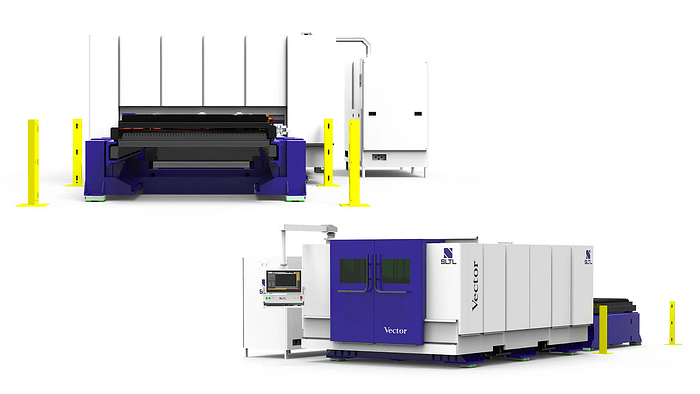

D. Fiber Laser Cutting Machine: The Pinnacle of Precision

Among these, Fiber Laser Cutting Machines emerge as the pinnacle of precision in cutting aluminium sheets. These machines, powered by rare-earth elements, offer unparalleled speed, accuracy, and versatility across a wide range of thicknesses.

Advantages of Fiber Laser Cutting for Aluminium

A. Unmatched Speed and Precision

Fiber Laser Cutting Machines stand out for their unmatched cutting speed and precision. In the competitive world of aluminium fabrication, where precision is paramount, these machines elevate your business to new heights.

B. Cost Efficiency for Your Business

Beyond precision, cost efficiency is a significant advantage of fiber laser cutting. Reduced energy consumption translates to lower operational costs, contributing to improved profitability for your Aluminium Fabrication Business.

C. Versatility Across Various Thicknesses

The ability to cut through aluminium sheets ranging from 1 mm to 100 mm in thickness positions Fiber Laser Cutting Machines as versatile tools. This flexibility enables your business to cater to diverse customer demands and industry requirements.

Choosing the Best Fiber Laser Cutting Machine

When choosing a Fiber Laser Cutting Machine, consider factors such as cutting speed, power, and the machine’s ability to handle various aluminium thicknesses.

A. Criteria for Selection

Opt for a machine that aligns with the specific needs and scale of your fabrication business. Consider the volume of production, the complexity of designs, and the overall efficiency offered by the machine.

B. Spotlight on the Superiority of Fiber Laser Technology

The exceptional performance of fiber laser technology stems from its high beam quality, ensuring clean and precise cuts. This superiority extends to the machine’s durability, reliability, and ease of maintenance, making it an investment that pays long-term dividends.

Utilizing Fiber Laser for High-Thickness Aluminium Sheets

A. Insights into High-Thickness Cutting

Aluminium sheets exceeding 1 mm in thickness require specialized attention. Fiber Laser Cutting Machines excel in handling high-thickness aluminium sheets, maintaining consistent performance across the entire spectrum.

B. Applications Across Industries

The applications of high-thickness aluminium cutting are diverse, ranging from automotive components to aerospace structures. The versatility of fiber laser cutting technology positions your Aluminium Fabrication Business as a reliable partner across various industries.

Understanding the Fiber Laser Cutting Process

A. Laser Focusing and Calibration

The precision of fiber laser cutting begins with accurate laser focusing. Calibration ensures the laser beam is aligned to achieve the desired cut quality, a crucial step in the cutting process.

B. Preparing Aluminium Sheets for Cutting

Proper material preparation involves ensuring the cleanliness and secure positioning of aluminium sheets on the cutting bed. This step contributes to the overall precision and quality of the final product.

C. Inputting Cutting Parameters for Accuracy

The efficiency of the cutting process is optimized by inputting the correct cutting parameters into the machine’s control system. These parameters dictate the cutting path, pattern, and other essential variables.

D. Executing the Efficient Cutting Process

With the parameters set, initiate the cutting process. Fiber Laser Cutting Machines swiftly and precisely cut through aluminium sheets, ensuring efficiency, accuracy, and a streamlined production flow.

Benefits of Fiber Laser Technology

A. Reducing Material Waste in Aluminium Fabrication

The precision of fiber laser cutting significantly reduces material waste in the aluminium fabrication process. This not only contributes to cost savings but also positions your business as environmentally conscious and sustainable.

B. Unleashing Enhanced Design Capabilities

Fiber laser cutting opens up new design possibilities. Complex and intricate patterns can be easily achieved, giving your Aluminium Fabrication Business a competitive edge in offering unique and customized solutions to clients.

C. Embracing Automation and Integration

Fiber Laser Cutting Machines can be seamlessly integrated with automation systems. Automated loading and unloading of materials, combined with computer numerical control (CNC) capabilities, enhance operational efficiency and reduce the need for manual labor.

Step-by-Step Guide: Using Fiber Laser for 1 mm to 100mm Aluminium Sheets

A. Setting Up the Fiber Laser Machine

Begin by calibrating the Fiber Laser Cutting Machine according to the specific thickness of the aluminium sheet. Input the cutting parameters into the machine’s control system for optimal results.

B. Safely Loading and Securing Aluminium Sheets

Ensure the aluminium sheets are clean and securely positioned on the cutting bed. Proper material preparation is crucial for the success of the cutting process.

C. Inputting Cutting Parameters for Accuracy

Load the cutting program into the machine’s control system. This program dictates the cutting path and pattern, ensuring accuracy and precision in the final product.

D. Executing the Efficient Cutting Process

Initiate the cutting process, and the Fiber Laser Cutting Machine will swiftly and precisely cut through the aluminium sheet. The high-speed nature of fiber lasers contributes to efficient production.

Industry Applications and Case Studies

A. Aluminium in Automotive Excellence

Explore how aluminium, cut with precision by Fiber Laser Cutting Machines, contributes to the production of lightweight and fuel-efficient automotive components.

B. Aerospace Innovations with Aluminium

Delve into the aerospace industry, where high-thickness aluminium sheets are transformed into intricate structures, showcasing the versatility and precision of fiber laser cutting technology.

C. Aluminium’s Role in Construction and Architecture

Witness how aluminium fabrication plays a pivotal role in construction and architecture. From structural components to intricate designs, the applications are vast and varied.

Overcoming Challenges in Aluminium Fabrication

A. Addressing Common Industry Challenges

Navigate challenges such as material inconsistencies, heat distortion, and design complexities. Fiber Laser Cutting Machines offer solutions to overcome these hurdles, ensuring consistent and high-quality results.

B. Operational Efficiency Tips for Success

Implement operational efficiency tips to streamline your Aluminium Fabrication Business. From optimized workflows to strategic equipment maintenance, these tips contribute to sustained success in the competitive industry.

Sustainability in Aluminium Fabrication

A. Green Practices for a Sustainable Business

Embrace environmentally friendly practices in aluminium fabrication. From sourcing recycled materials to implementing energy-efficient processes, your business can make a positive impact on sustainability.

B. Aluminium Recycling and Environmental Impact

Highlight the importance of aluminium recycling in your fabrication business. Discuss the environmental benefits and how recycling contributes to a circular economy.

Future Trends in Aluminium Fabrication

A. Emerging Technologies Shaping the Industry

Stay ahead of the curve by exploring emerging technologies in aluminium fabrication. From advancements in automation to innovative materials, staying informed positions your business for future success.

B. Navigating the Evolving Landscape

Adapt to the evolving landscape of the Aluminium Industry. Explore new markets, technologies, and trends to ensure your Aluminium Fabrication Business remains at the forefront of industry developments.

Conclusion

A. Recap of Essential Steps

In conclusion, establishing and growing an Aluminium Fabrication Business requires a strategic approach. From crafting a solid foundation to embracing cutting-edge technology, each step contributes to the success of your venture.

B. A Look Ahead at the Aluminium Fabrication Journey

As you embark on your aluminium fabrication journey, keep an eye on industry trends, technological advancements, and sustainability practices. Staying informed and agile positions your business for sustained growth and excellence.

.png)

Comments

Post a Comment