Cutting Through Boundaries: How High Power Fiber Lasers Are Reshaping the Metal Fabrication Industry?

Innovation and technology continue to reshape the landscape of metal manufacturing. One such innovation that has been causing a significant stir is the emergence of high-power fiber lasers. These cutting-edge tools are revolutionizing the metal fabrication industry, pushing the boundaries of what was once thought possible. We'll look at high-power fiber lasers and how they're changing the metal fabrication business, with an emphasis on the SLTL Laser Cutting Machine - Infinity F1 and other cutting-edge laser technologies.

Unveiling

the Power of High-Power Fiber Lasers

High-power fiber lasers have become the gold standard in

precision cutting and welding. Unlike traditional CO2 lasers, fiber lasers utilize

optical fibers as their gain medium, allowing for a more concentrated, intense

beam of light. This concentrated beam results in superior precision and

efficiency in metal cutting, making it a game-changer for various industries.

The

Advantages of Fiber Lasers

Unmatched

Precision: Fiber lasers offer an exceptional level of precision,

enabling manufacturers to achieve intricate cuts and designs that were once

considered too complex. This level of accuracy reduces material waste and

rework, ultimately saving time and resources.

Speed and

Efficiency: The concentrated beam of fiber lasers translates to

faster cutting speeds. This efficiency is crucial in meeting tight production

deadlines and handling large-scale projects without compromising quality.

Versatility: High-power

fiber lasers can effectively cut a wide range of materials, from metals like Mild

steel, Stainless steel, Aluminum, Brass, Copper, Galvanized Iron, Coated Sheet,

Others. This versatility opens up new possibilities for manufacturers across

different industries.

Cost Savings: While

the initial investment in fiber laser technology might be higher, the long-term

cost savings are substantial. The combination of reduced material waste, energy

efficiency, and minimal maintenance leads to a more cost-effective operation.

The SLTL

Laser Cutting Machine - Infinity F1: Redefining Metal Fabrication

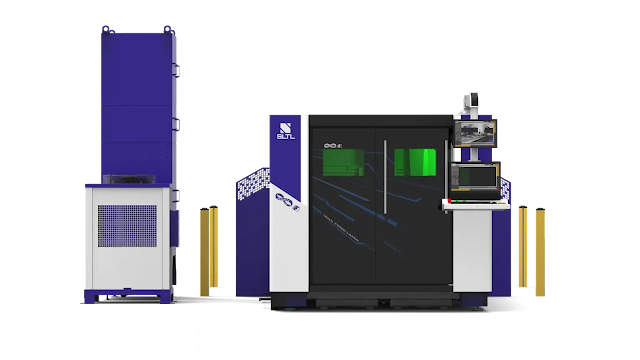

Among the pioneers of high-power fiber laser technology is

SLTL Group, with their flagship model, the Infinity F1. This advanced CNC laser cutting machine has garnered

attention for its cutting-edge features and impressive capabilities.

Unparalleled

Precision and Speed

The Infinity F1 boasts a cutting-edge design that maximizes precision and speed. With its high-power fiber laser source, it can effortlessly handle intricate designs and complex cuts, all while maintaining exceptional accuracy. This makes it a sought-after tool for industries requiring intricate components and high-volume production.

Smart and

Intuitive Operation

The machine's user-friendly interface and software make it accessible to both experienced operators and newcomers. Its intuitive controls allow for easy customization and quick setup, reducing downtime between tasks. This ensures a seamless workflow and optimal utilization of resources.

Adaptable

to Diverse Materials

One of the standout features of the Infinity F1 is its

ability to cut a wide variety of materials with precision. Whether it's thin

sheets of metal or thicker materials, this machine can handle the task

effectively, making it a versatile asset for businesses dealing with diverse

materials.

Exploring

Laser Cutting Possibilities

Beyond the SLTL Infinity F1, the world of laser cutting

offers a range of options tailored to different needs.

Fiber Laser

Cutter

Fiber laser cutters, in general, are becoming synonymous

with efficiency and accuracy. Their solid-state design, absence of moving

parts, and minimal maintenance make them an attractive choice for businesses

looking to optimize their operations.

CNC Cutting

Technology

Computer Numerical Control (CNC) technology has taken laser

cutting to new heights. The precision and automation offered by CNC laser

cutting machines enhance productivity and reduce human error, leading to consistent,

high-quality output.

High Power

Laser Cutter: Pushing the Limits

High-power laser cutters, such as the Infinity F1,

demonstrate the potential of pushing laser technology to its limits. With power

ratings of up to 60 KW, these machines can tackle thick materials and achieve

remarkable speeds without compromising precision.

Embracing

the Future: The Impact and Beyond

The integration of high-power fiber lasers into the metal

fabrication industry is not just a technological leap; it's a paradigm shift.

As these tools continue to evolve, we can expect even greater precision, faster

speeds, and expanded material capabilities. However, as with any advancement,

questions arise.

What Lies

Ahead for Traditional Methods?

The rise of high-power fiber lasers prompts us to question

the relevance of traditional cutting methods. While they may not become

obsolete, their limitations are more apparent, pushing industries to consider

upgrading their equipment to stay competitive.

Balancing

Automation and Craftsmanship

As automation becomes more prevalent, there's a concern

about the loss of craftsmanship. Striking a balance between automated precision

and the artistic touch of skilled craftsmen will be a challenge the industry

must navigate.

Environmental

Considerations

With greater power comes increased energy consumption. The

industry must address the environmental impact of high-power fiber lasers and

work towards sustainable solutions without compromising productivity.

Conclusion:

Shaping the Future of Metal Fabrication

In conclusion, the advent of high-power fiber lasers,

exemplified by the SLTL Laser Cutting Machine - Infinity F1, marks a turning

point in the metal fabrication industry. Their precision, speed, and versatility

are rewriting the rules and opening doors to new possibilities. As we journey

into this future, it's imperative for businesses to embrace the potential of

these technologies while staying mindful of the challenges and responsibilities

that come with them. The fusion of human ingenuity and cutting-edge tools will

define the next chapter of metal fabrication's evolution.

.png)

Comments

Post a Comment